Proper maintenance of directional control valves is essential for the reliability and efficiency of pneumatic and hydraulic systems. These valves control the flow and direction of fluids, playing a pivotal role in various industrial applications. Regular maintenance includes cleaning, lubrication, and inspection for wear and tear. Neglecting maintenance can lead to valve malfunctions, leaks, and system failures, potentially causing costly downtime and safety risks. By prioritizing the upkeep of directional control valves, you ensure the smooth operation of your machinery, prolong the valves' lifespan, and minimize the chances of unexpected breakdowns.

Friday, October 13, 2023

The Importance of Properly Maintaining Directional Control Valves

Tuesday, September 26, 2023

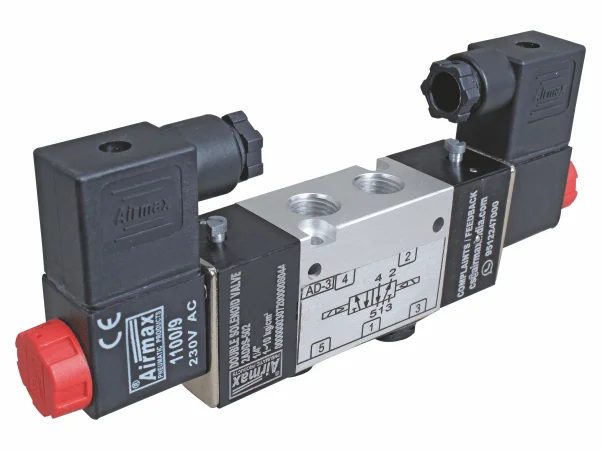

Applications and Advantages of 3/2 Double Solenoid Valves

3/2 Double Solenoid Valves find extensive use in various pneumatic and fluid control systems. These valves offer versatile solutions for switching between two distinct flow paths, making them ideal for applications where precise control is essential.

Their advantages include rapid response times, enabling quick changes in flow direction, and reliability in demanding environments. Common uses include automation, industrial machinery, and robotics, where these valves ensure efficient and precise fluid control, contributing to improved system performance and productivity.

Industrial Automation and Control

Industrial automation relies on a multitude of components and technologies to streamline manufacturing processes and improve efficiency. One of the key elements in this ecosystem is the 3/2 Double Solenoid Valve. These valves play a crucial role in controlling the flow of air or other gases in automated systems.

In industrial automation, the 3/2 Double Solenoid Valve serves as a fundamental tool for controlling the movement of pneumatic actuators. These actuators are responsible for tasks such as opening and closing valves, moving conveyor belts, and handling materials. The valve's ability to quickly switch between two flow paths allows precise control of these actuators, enabling machinery to perform tasks with accuracy and speed.

Enhanced Precision in Robotics

Robotics is another domain where 3/2 Double Solenoid Valves find extensive use. Robots require precise control over their movements, and pneumatic systems are often used to achieve this level of control. The 3/2 Double Solenoid Valve is a critical component in these systems.

In robotics, these valves enable fine-tuned control over pneumatic actuators responsible for tasks like gripping, lifting, and rotating. Their rapid response times and ability to switch between two flow paths swiftly allow robots to carry out complex operations with enhanced precision. Whether in manufacturing, warehousing, or medical applications, the use of these valves ensures robots can perform their tasks accurately and efficiently.

Fluid Control in Pneumatic Systems

Pneumatic systems are widely employed in various industrial applications due to their simplicity, reliability, and cost-effectiveness. These systems rely on the controlled flow of air or gas to power machinery and perform various tasks. The 3/2 Double Solenoid Valve is a critical component in pneumatic systems, serving as the control center for fluid flow.

In pneumatic systems, these valves manage the direction of airflow, enabling the activation and deactivation of pneumatic actuators. This control is essential for processes such as material handling, clamping, and positioning. The valves allow for seamless transitions between pressurized and exhaust states, ensuring the system operates smoothly and efficiently.

Quick and Reliable Flow Reversal

One of the standout features of the 3/2 Double Solenoid Valve is its ability to provide quick and reliable flow reversal. This capability is particularly valuable in applications where rapid changes in fluid direction are required.

In tasks like machine part ejection, sorting, and diverting materials on conveyor belts, the valve's swift flow reversal is instrumental in achieving precise and timely actions. The reliability of these valves ensures that processes continue uninterrupted, minimizing downtime and improving overall productivity.

Versatility for Diverse Applications

Perhaps one of the most notable advantages of 3/2 Double Solenoid Valves is their versatility. These valves can be adapted to a wide range of applications across various industries. Their design allows for customization in terms of materials, sizes, and configurations to suit specific needs.

Whether in automotive manufacturing, food processing, pharmaceuticals, or packaging, these valves can be tailored to meet the demands of different environments and processes. Their adaptability and reliability make them a go-to choice for engineers and system designers seeking flexible solutions for fluid control.

In conclusion, 3/2 Double Solenoid Valves play a pivotal role in industrial automation and control, robotics, pneumatic systems, and many other applications. Their ability to provide precision, reliability, and quick flow reversal makes them indispensable components in modern manufacturing and automation processes. Their versatility ensures they remain a cornerstone technology for engineers and industries seeking efficient and precise fluid control solutions.

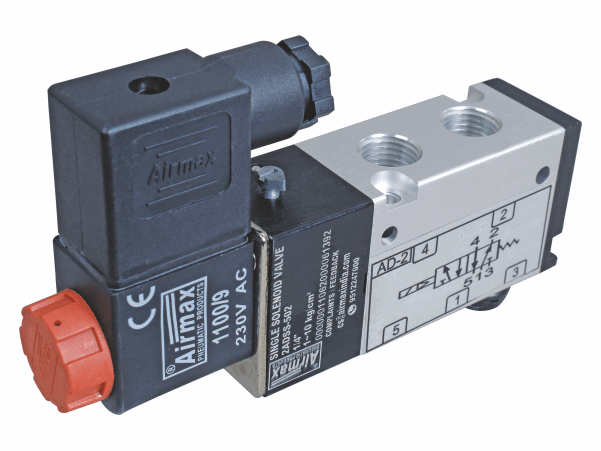

Custom Single Solenoid Valves: Tailored Solutions for Your Needs

Custom single solenoid valves are the epitome of tailored solutions for specific requirements. When seeking precision and efficiency, partnering with a reputable single solenoid valve manufacturer is crucial. These manufacturers possess the expertise to design and produce bespoke solutions that perfectly align with your needs. From unique applications to specialized materials, custom single solenoid valves ensure optimal performance. Join us in exploring the world of tailored solenoid valve solutions, where a trusted manufacturer can craft the precise components you require to enhance your operations.

Understanding the Benefits of Customization

Custom single solenoid valves offer a wide range of advantages over off-the-shelf solutions. These benefits stem from tailoring the valve to meet the specific needs of your application, resulting in improved performance, efficiency, and overall effectiveness.

One of the primary benefits is enhanced functionality. By customizing the solenoid valve, you can ensure that it precisely matches the requirements of your system. This can lead to more precise control over fluid or gas flow, reducing waste and energy consumption.

Additionally, customization can optimize the valve's size and shape to fit the available space within your machinery or system. This efficient use of space can be critical in industries where every square inch counts.

Customization also allows for the selection of materials and components that best suit your application's environment. Whether you require resistance to extreme temperatures, chemicals, or corrosive substances, tailored solenoid valves can provide the durability and reliability needed to withstand challenging conditions.

Precision Engineering for Your Specific Application

Precision engineering is a hallmark of custom single solenoid valves. Manufacturers work closely with you to understand the exact requirements of your application, including factors like flow rates, pressure levels, response times, and compatibility with other system components.

This precision extends to the valve's design and construction. Each component is carefully selected and assembled to ensure optimal performance and longevity. This level of detail ensures that the custom valve meets or exceeds your expectations.

Manufacturers employ advanced engineering techniques, such as computer-aided design (CAD) and finite element analysis (FEA), to fine-tune every aspect of the valve. This results in a product that not only functions flawlessly but also contributes to the overall efficiency and reliability of your system.

Materials and Configurations: Your Choices, Your Solenoid Valve

Customization extends to the choice of materials and configurations for your solenoid valve. Depending on your application's requirements, you can select materials that offer resistance to corrosion, high temperatures, or specific chemicals. Common materials include stainless steel, brass, and various plastics.

Moreover, you can specify the valve's configuration, including the number of ports and positions, to precisely match your system's needs. Whether you require a two-way, three-way, or four-way valve, custom manufacturers can create the ideal configuration for your application.

Customization also extends to the electrical specifications of the solenoid, allowing you to choose voltage, current, and other electrical characteristics that integrate seamlessly with your control system.

Quality Assurance in Custom Solenoid Valve Manufacturing

Quality assurance is a critical aspect of custom solenoid valve manufacturing. Reputable manufacturers adhere to strict quality control procedures throughout the design and production processes. This ensures that every custom valve meets stringent performance and safety standards.

Quality assurance includes rigorous testing of each valve before it leaves the factory. Testing may encompass functional checks, pressure tests, and environmental tests to ensure that the valve operates flawlessly under real-world conditions.

Furthermore, manufacturers often provide documentation and certification for their custom solenoid valves, giving you peace of mind that the product you receive is of the highest quality and reliability.

Applications Across Diverse Industries: Where Customization Matters

Custom single solenoid valves find applications across a wide range of industries, emphasizing the importance of customization in meeting specific needs.

In the automotive industry, custom solenoid valves are used in transmission systems, fuel injection, and emission control, where precise control is essential for optimal performance and efficiency.

In the medical field, customized valves are crucial in various applications, including ventilators, diagnostic equipment, and fluid handling systems. These valves must meet stringent safety and performance standards.

The aerospace sector relies on custom solenoid valves for tasks such as controlling aircraft landing gear, engine thrust vectoring and hydraulic systems. Precision and reliability are paramount in this industry.

In industrial automation, customized solenoid valves are essential components in assembly lines, robotics, and manufacturing processes where rapid, precise control of fluids or gases is required.

Custom single solenoid valves also play a critical role in the oil and gas industry, chemical processing, and water treatment, where they must withstand harsh environmental conditions and corrosive substances.

In conclusion, custom single solenoid valves offer numerous benefits, including enhanced functionality, precision engineering, material choices, and rigorous quality assurance. Their applications span a wide range of industries, underlining the importance of customization in meeting specific needs and ensuring optimal performance and reliability in diverse applications.

Saturday, September 16, 2023

Finding the Right Double Solenoid Valve Manufacturer for Your Industry

Solenoid valves are crucial components in various industries, playing a pivotal role in controlling the flow of fluids and gases. Among these, double solenoid valves hold a special place for their ability to provide precise and reliable operation. When it comes to selecting a manufacturer for these critical components, there are several factors to consider. This article aims to guide you through the process of finding the right double solenoid valve manufacturer for your industry, ensuring optimal performance and efficiency.

Expertise and Experience

The first and foremost consideration is the manufacturer's expertise and experience in producing double solenoid valves. An established manufacturer with a track record of producing high-quality valves is more likely to deliver reliable products that meet industry standards.

Product Range and Customization Options

Different industries have unique requirements when it comes to double solenoid valves. A reputable manufacturer should offer a wide range of products to cater to various applications. Additionally, they should provide customization options, allowing you to tailor the valves to your specific needs.

Technical Support and After-Sales Service

Technical support and after-sales service are crucial aspects of a successful partnership with a valve manufacturer. They should have a dedicated support team to assist with any technical queries or issues that may arise during installation or operation.

Reliability and Durability

The reliability and durability of double solenoid valves are of utmost importance. The manufacturer should use high-quality materials and employ advanced manufacturing techniques to ensure that their valves can withstand harsh operating conditions.

Cost-Effectiveness

It's important to strike a balance between cost-effectiveness and the quality of the product. A cheaper valve that fails prematurely can end up costing more in the long run due to downtime and replacement costs.

Reviews and Testimonials

Customer reviews and testimonials provide valuable insights into the reputation and performance of a manufacturer. Look for feedback from other industries similar to yours to get an idea of the manufacturer's suitability for your specific needs.

Introducing Airmax Pneumatic: Your Trusted Partner in Solenoid Valves

When it comes to finding the right double solenoid valve manufacturer for your industry, look no further than Airmax Pneumatic. With a legacy of excellence and a commitment to innovation, Airmax Pneumatic has established itself as a leading name in the industry.

About Airmax Pneumatic

Airmax Pneumatic is a distinguished manufacturer of high-quality pneumatic components, including a comprehensive range of solenoid valves. With over two decades of experience, Airmax Pneumatic has earned a reputation for delivering precision-engineered solutions that meet the exacting demands of various industries.

Why Choose Airmax Pneumatic?

Unmatched Expertise: With a team of skilled engineers and technicians, Airmax Pneumatic brings a wealth of expertise to the table. Their in-depth knowledge of solenoid valve technology ensures that you receive products of the highest quality.

Extensive Product Range: Airmax Pneumatic offers a diverse range of double solenoid valves, catering to a wide spectrum of industrial applications. Whether you require standard configurations or custom solutions, Airmax Pneumatic has you covered.

Stringent Quality Control: Quality is the cornerstone of Airmax Pneumatic's operations. Their valves undergo rigorous testing and inspection processes to guarantee optimal performance and reliability.

Technical Support: Airmax Pneumatic provides exceptional technical support to assist you at every stage, from selection to installation and beyond.

Competitive Pricing: Airmax Pneumatic understands the importance of cost-effectiveness. They offer competitive pricing without compromising on the quality and durability of their products.

Conclusion

Selecting the right double solenoid valve manufacturer is a critical decision that can impact the efficiency and reliability of your industrial operations. By considering factors such as expertise, product range, quality assurance, and customer feedback, you can make an informed choice.

Saturday, August 19, 2023

Modern Industrial Applications of 5 Way 2 Position Pneumatic Valve

Introduction to 5 Way 2 Position Pneumatic Valve

The 5 Way 2 Position Pneumatic Valve is a vital component within pneumatic systems that control the flow of compressed air or gases. It operates in two distinct positions – open and closed, and it can connect and disconnect different air passages within a pneumatic circuit.

How Does a 5 Way 2 Position Pneumatic Valve Work?

In its basic form, the 5 Way 2 Position Pneumatic Valve consists of five ports and two positions. These ports facilitate the entry and exit of compressed air or gases. When in the closed position, the valve blocks airflow between certain ports, while in the open position, it allows airflow to pass through. This dynamic control over airflow is crucial for directing the movement of pneumatic cylinders, actuators, and other components in a wide array of applications.

Advantages of Using 5 Way 2 Position Pneumatic Valve

- • Quick Response: These valves offer rapid switching capabilities, enabling timely control of pneumatic actuators, which is essential for many industrial processes.

- • Simplicity: Their design is relatively simple, making them easy to install, operate, and maintain.

- • Durability: Constructed from sturdy materials, these valves are capable of withstanding harsh industrial environments.

- • Cost-Effective: They provide an economical solution for controlling pneumatic systems compared to more complex alternatives.

Industrial Applications

Automotive Manufacturing

In automotive assembly lines, 5 Way 2 Position Pneumatic Valves are employed to control robotic arms, pneumatic presses, and conveyor systems. These valves enable precision in tasks like welding, painting, and component assembly.

Packaging Industry

Pneumatic systems with these valves find applications in packaging machines, ensuring accurate filling, sealing, and labeling processes in industries ranging from food to cosmetics.

Food Processing

Maintaining hygiene and precision is critical in the food industry. Pneumatic valves are used to regulate the movement of conveyor belts, sorting mechanisms, and packaging lines.

Pharmaceuticals

In the pharmaceutical sector, these valves contribute to the automation of drug production, from precise mixing of ingredients to packaging and labeling.

Textile Industry

Pneumatic valves play a role in controlling the dyeing, printing, and finishing processes in textile manufacturing, ensuring consistent and uniform results.

Robotics and Automation

5 Way 2 Position Pneumatic Valves are essential in robotic systems, controlling the movement of robot arms, grippers, and other components.

Aerospace Industry

From assembly to testing, pneumatic valves are integral to aerospace manufacturing, aiding in tasks like riveting, drilling, and painting.

Chemical Processing

In chemical plants, these valves regulate the flow of chemicals, ensuring accurate mixing and distribution.

Petrochemical Industry

Similar to chemical processing, pneumatic valves contribute to the safe and efficient handling of petrochemicals.

HVAC Systems

Heating, ventilation, and air conditioning systems utilize these valves for controlling airflow, ensuring optimal indoor comfort.

Integration of Airmax Pneumatic Valve

As a leader in pneumatic technology, Airmax Pneumatic offers a range of innovative 5 Way 2 Position Pneumatic Valves designed to meet the demands of modern industrial automation. With a focus on precision, reliability, and efficiency, Airmax Pneumatic valves seamlessly integrate into various applications, enhancing overall system performance.

Conclusion

The 5 Way 2 Position Pneumatic Valve stands as a cornerstone in modern industrial applications, driving automation, efficiency, and precision across diverse sectors. Its role in controlling pneumatic systems is indispensable, enabling industries to achieve higher productivity and quality standards.

Friday, June 23, 2023

Unveiling the Secrets of Pneumatic Valves Maximizing Productivity and Safety

Introduction:

Pneumatic valves are the unsung heroes of modern industrial automation. Understanding the secrets behind pneumatic valves is essential for maximizing productivity and ensuring a safe working environment.

Maximizing Productivity with Pneumatic Valves:

Pneumatic valves serve as the gateway to automation in many industries. By regulating the flow, pressure, and direction of air, pneumatic valves enable precise positioning, rapid actuation, and efficient energy usage in automated systems.

These valves can open and close rapidly, resulting in quick response times and high-speed operation. This characteristic is particularly beneficial in industries that require fast and accurate movements, such as manufacturing, assembly lines, and robotics.

Furthermore, pneumatic valve offer excellent repeatability, ensuring consistent and reliable performance. With proper calibration and maintenance, these valves can provide long-lasting and predictable operation, reducing downtime and enhancing overall productivity.Safety Considerations:

In addition to productivity, safety is of paramount importance in industrial settings. Properly designed and maintained pneumatic valves help prevent accidents, leaks, and over-pressurization, safeguarding both equipment and personnel.

Airmax Pneumatic: Leading the Way in Pneumatic Valve Solutions

With years of experience and expertise, Airmax Pneumatic has been at the forefront of developing innovative valve solutions that maximize productivity and ensure safety.

These valves are engineered with precision and manufactured to the highest standards, ensuring reliability and optimal performance in diverse industrial applications.

Airmax Pneumatic's valves undergo thorough inspections and performance tests to guarantee their durability and efficiency in demanding environments.

Moreover, Airmax Pneumatic provides comprehensive support and technical assistance to its customers. Their team of knowledgeable professionals can assist in valve selection, installation, and troubleshooting, ensuring that the valves integrate seamlessly into existing systems and deliver the desired results.

Conclusion:

Pneumatic valves are indispensable components in modern industrial automation. Understanding their secrets is vital for maximizing productivity and maintaining a safe working environment. Airmax Pneumatic, with its dedication to quality and innovative valve solutions, is a reliable partner in achieving these goals. By leveraging the power of pneumatic valves and partnering with reputable companies like Airmax Pneumatic, industries can unlock new levels of productivity, efficiency, and safety in their operations.

Wednesday, June 7, 2023

Demystifying Pneumatic Directional Control Valves Everything You Need to Know

Introduction:

These valves play a vital role in various industrial applications, from manufacturing and automation to robotics and machinery. Additionally, we will highlight the expertise and offerings of Airmax, a leading company in the pneumatic industry.

Understanding Pneumatic Directional Control Valves:

They control the direction, flow rate, and pressure of the air, enabling the system to perform specific tasks. These valves are typically composed of a valve body, spool, actuator, and ports. The spool inside the valve body moves to open or close different air passages, directing the airflow accordingly.

Types of Pneumatic Directional Control Valves:

- 3-Way Valves: These valves have three ports and can control the flow of air between two different paths. They are commonly used for cylinder control in pneumatic systems.

- 4-Way Valves: These valves have four ports and are capable of controlling the direction of airflow to two different actuators. They are extensively used in complex pneumatic systems.

- 5-Way Valves: These valves have five ports and can control the flow of air to two actuators, along with an exhaust port. They are widely employed in applications requiring multiple actuators to operate simultaneously.

Applications of Pneumatic Directional Control Valves:

- Pneumatic directional control valves find applications across various industries due to their reliability, durability, and precise control capabilities. Some common applications include:

- Manufacturing and Automation: Pneumatic directional control valves are extensively used in manufacturing processes and automated systems. They control the movements of actuators, such as cylinders and motors, to perform tasks like material handling, assembly, and packaging.

- Machinery and Equipment: Pneumatic directional control valve are integral to the operation of machinery and equipment in industries such as agriculture, construction, and mining

- HVAC Systems: Pneumatic directional control valves are used in heating, ventilation, and air conditioning (HVAC) systems to regulate airflow and control dampers.

The Airmax Advantage:

With years of experience and expertise, Airmax offers a wide range of pneumatic directional control valves tailored to meet diverse application requirements.

Airmax prides itself on its commitment to customer satisfaction. Their team of knowledgeable professionals provides expert guidance in selecting the right pneumatic directional control valves for specific applications. Additionally, Airmax offers comprehensive after-sales support, including installation assistance, maintenance, and troubleshooting.

Conclusion:

Pneumatic directional control valves are essential components in pneumatic systems, enabling precise control of airflow for a wide range of applications. Understanding the different types of valves, their applications, and benefits is crucial for anyone working with pneumatic systems. When seeking reliable and top-quality pneumatic products, Airmax stands as a trusted partner, offering a diverse range of pneumatic directional control valves and exceptional customer service. By partnering with Airmax, you can ensure optimal performance, efficiency, and reliability in your pneumatic applications.

Directional Control Valve Solutions

In industries where precision, reliability, and efficiency are paramount, the choice of directional control valves plays a pivotal role. The...

-

Advanced showcasing offices assume a major part in aiding individual brands and organizations leave their imprint on the web. Without the a...

-

Rotary union water systems play a pivotal role in various industrial applications, facilitating the seamless transfer of water between sta...

-

8 edges of partaking SEO Agencies to spice up Your Online Presence! Promoting has modified to maybe the foremost requesting and important s...