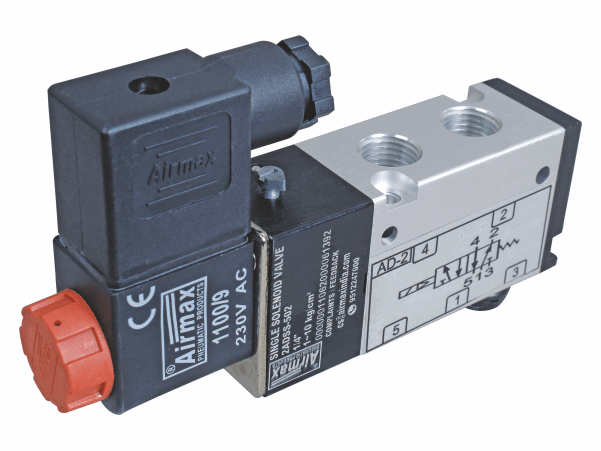

Custom single solenoid valves are the epitome of tailored solutions for specific requirements. When seeking precision and efficiency, partnering with a reputable single solenoid valve manufacturer is crucial. These manufacturers possess the expertise to design and produce bespoke solutions that perfectly align with your needs. From unique applications to specialized materials, custom single solenoid valves ensure optimal performance. Join us in exploring the world of tailored solenoid valve solutions, where a trusted manufacturer can craft the precise components you require to enhance your operations.

Understanding the Benefits of Customization

Custom single solenoid valves offer a wide range of advantages over off-the-shelf solutions. These benefits stem from tailoring the valve to meet the specific needs of your application, resulting in improved performance, efficiency, and overall effectiveness.

One of the primary benefits is enhanced functionality. By customizing the solenoid valve, you can ensure that it precisely matches the requirements of your system. This can lead to more precise control over fluid or gas flow, reducing waste and energy consumption.

Additionally, customization can optimize the valve's size and shape to fit the available space within your machinery or system. This efficient use of space can be critical in industries where every square inch counts.

Customization also allows for the selection of materials and components that best suit your application's environment. Whether you require resistance to extreme temperatures, chemicals, or corrosive substances, tailored solenoid valves can provide the durability and reliability needed to withstand challenging conditions.

Precision Engineering for Your Specific Application

Precision engineering is a hallmark of custom single solenoid valves. Manufacturers work closely with you to understand the exact requirements of your application, including factors like flow rates, pressure levels, response times, and compatibility with other system components.

This precision extends to the valve's design and construction. Each component is carefully selected and assembled to ensure optimal performance and longevity. This level of detail ensures that the custom valve meets or exceeds your expectations.

Manufacturers employ advanced engineering techniques, such as computer-aided design (CAD) and finite element analysis (FEA), to fine-tune every aspect of the valve. This results in a product that not only functions flawlessly but also contributes to the overall efficiency and reliability of your system.

Materials and Configurations: Your Choices, Your Solenoid Valve

Customization extends to the choice of materials and configurations for your solenoid valve. Depending on your application's requirements, you can select materials that offer resistance to corrosion, high temperatures, or specific chemicals. Common materials include stainless steel, brass, and various plastics.

Moreover, you can specify the valve's configuration, including the number of ports and positions, to precisely match your system's needs. Whether you require a two-way, three-way, or four-way valve, custom manufacturers can create the ideal configuration for your application.

Customization also extends to the electrical specifications of the solenoid, allowing you to choose voltage, current, and other electrical characteristics that integrate seamlessly with your control system.

Quality Assurance in Custom Solenoid Valve Manufacturing

Quality assurance is a critical aspect of custom solenoid valve manufacturing. Reputable manufacturers adhere to strict quality control procedures throughout the design and production processes. This ensures that every custom valve meets stringent performance and safety standards.

Quality assurance includes rigorous testing of each valve before it leaves the factory. Testing may encompass functional checks, pressure tests, and environmental tests to ensure that the valve operates flawlessly under real-world conditions.

Furthermore, manufacturers often provide documentation and certification for their custom solenoid valves, giving you peace of mind that the product you receive is of the highest quality and reliability.

Applications Across Diverse Industries: Where Customization Matters

Custom single solenoid valves find applications across a wide range of industries, emphasizing the importance of customization in meeting specific needs.

In the automotive industry, custom solenoid valves are used in transmission systems, fuel injection, and emission control, where precise control is essential for optimal performance and efficiency.

In the medical field, customized valves are crucial in various applications, including ventilators, diagnostic equipment, and fluid handling systems. These valves must meet stringent safety and performance standards.

The aerospace sector relies on custom solenoid valves for tasks such as controlling aircraft landing gear, engine thrust vectoring and hydraulic systems. Precision and reliability are paramount in this industry.

In industrial automation, customized solenoid valves are essential components in assembly lines, robotics, and manufacturing processes where rapid, precise control of fluids or gases is required.

Custom single solenoid valves also play a critical role in the oil and gas industry, chemical processing, and water treatment, where they must withstand harsh environmental conditions and corrosive substances.

In conclusion, custom single solenoid valves offer numerous benefits, including enhanced functionality, precision engineering, material choices, and rigorous quality assurance. Their applications span a wide range of industries, underlining the importance of customization in meeting specific needs and ensuring optimal performance and reliability in diverse applications.

No comments:

Post a Comment